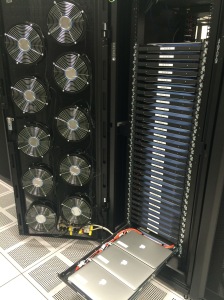

96 MacBook Pro’s in a single Rack space

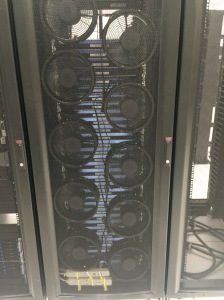

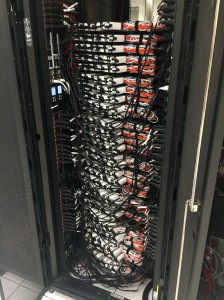

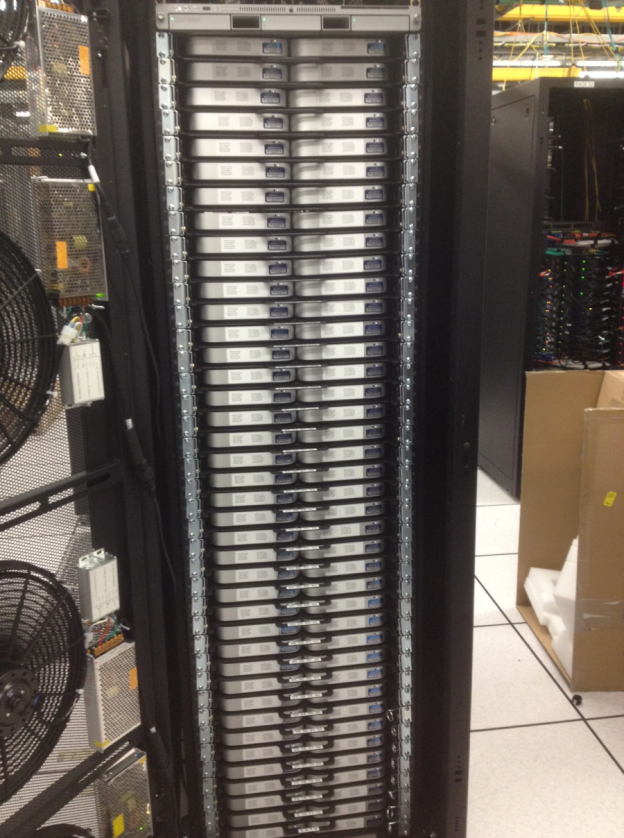

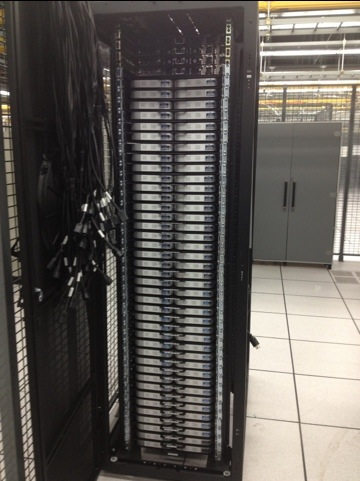

We had a need to introduce 96 MacBook Pro’s for our product testing. Our requirements included Retina displays, small form factor, low power, cool running, Apple branded hardware, high density design, i7 CPU’s, 16GB RAM, etc… This is what I came up with. Some of the parts are custom 3D printed and others are standard off the shelf parts. We use 3D printed wedges to keep each lid open to 7mm, and other 3D printed parts to help hold the power bricks to the cable management arm. I know some of you will reply with the standard “Why didn’t you just use Linux?” or “Just use OS X in a VM on <insert hardware name here>”, but the testing we do requires Apple branded hardware, so this is what we came up with. This rack has been in service for a few months now and is running great.

Here are some of the pictures:

Shelf pulled out. Notice 3 MacBook Pro’s nested together. They are actually being held open 7mm by a custom 3D printed wedge. This opening allows for the screen to be used for testing as well as ample air circulation. You can’t see the temperature sensors tucked into each notebook’s keyboard area.